新闻中心

新闻中心进口真空泵前十名_罗茨鼓风机

进口真空泵前十名:目前市场上知名的进口真空泵品牌

1850年,LEYBOLD莱宝公司在德国科隆成立。自公司成立以来,莱宝一直走在世界真空技术发展的前端。目前,莱宝公司是世界上著名的真空设备供应商之一。LEYBOLD在世界上四个国家设有工厂,每家工厂各自生产不同系列的真空元部件。其中有位于:德国的科隆,公司总部所在地。几乎生产所有系列的产品;美国的宾西法尼亚州,专门生产应用于半导体行业的干泵、低温泵等;法国的瓦郎斯,专门生产SOGEVAC系列单级旋片泵;

进口真空泵前十名:进口水环式真空泵(欧美进口十大品牌)

英国GRIMM格林进口水环式真空泵 UK GRIMM imported water ring vacuum pump

英国GRIMM格林进口水环式真空泵概述:

进口水环真空泵及压缩机是用来抽吸或压送气体和其它无腐蚀性、不溶于水、不含固体颗粒的气体,以便在密闭容器中形成真空或压力,满足工艺流程要求,吸入或压送的气体中允许混有少量的液体。

英国GRIMM格林进口水环式真空泵工作原理:

叶轮偏心地安装在泵体内,因此当叶轮旋转时,水受离心力的作用而在泵体内壁形成一旋转水环,水环上部内表面与轮毂相切沿箭头方向旋转,在前半转过程中,水环内表面逐渐与轮毂脱离,因此在叶轮叶片间与水环形成封闭空间,随着叶轮的旋转,该空间逐渐扩大,空间气体压力降低,气体被及入空间;在后半转过程中,水环内表面渐渐与轮毂靠近,叶片间的空间逐渐缩小,空间气体压力升高,高于排气口时,叶片间的气体被排出。如此叶轮每转动一周,叶片间的空间吸排一次,许多空间不停地工作,泵就连续不断地抽吸或压送气体。

由于在工作过程中,做功产生热量,会使工作水环发热,同时一部分水和气体一起被排走,因此,在工作过程中,必须不断地给泵供水,以冷却和补充泵内消耗的水,满足泵的工作要求。

当泵排出的气体不再利用时,在泵排气一端接有气水分离器(可自己制作一水箱代替),废水和所带的部分水排入气水分离器后,气水分离,气体由排气管排出,留下的水经回水管供至泵内继续使用。随着工作时间的延长,工作水温度会不断地升高,这时需从气水分离器供水处供给一定的冷水(自来水),以降低工作水的温度,保证泵能达到所要求的技术要求和指标。

当作为压缩机使用时,泵排气口接有气水分离器,气水混合物进入气水分离器后自动分离,气体由排气管输送到所需系统而工作水经过自动溢于开关放出,压缩气体时,工作水易发热,水由泵出口排出,温度会变得较高,因此在气水分离器的底部,要不断地供给冷水,以补充被放走的热水,同时起冷却作用,使工作水温度不致过高,从而保证压缩机性能,达到技术指标,满足工艺要求。

英国GRIMM格林进口水环式真空泵结构说明:

进口水环式真空泵由泵体、两个端盖、叶轮、轴等部件组成。进气管和排气管通过安装在端盖上的园盘上的吸气孔和排气孔与泵腔相连,轴偏心地安装在泵体中,叶轮用平键固定在轴上。水环式真空泵两端面的总间隙由泵体和园盘之间的垫来调整,叶轮与端盖上的园盘之间的间隙由轴套(SK-1.5/3/6)或背帽(SK-12/20/30)推动叶轮来调整,而SK-42以上轴与叶轮为过盈配合,此间隙由前端定位时确定,SK-42/60/85/120无轴套,其余结构与SK-6/12/20/30相同。叶轮两端面与端盖园盘的间隙决定气体在泵腔内由进气口至排气口流动中损失的大小及限压力。

进口水环式真空泵填料安装在两端盖内,密封不经由端盖中的小孔进入填料中,冷却填料及加强密封效果。叶轮形成水环所需的补充水由供水管供给,供水管可与气水分离器连在一起循环供水。

SK型水环式真空泵密封形式采用机械密封,机械密封安装在填料空腔里,填料省略。填料压盖换成机械密封压盖,其余结构相同。

轴承由园螺母固定在轴上。

进口水环式真空泵在端盖上安装有园盘,园盘上设有吸、排气孔和橡胶球阀。橡胶球阀的作用是当叶轮叶片间的气体压力达到排气压力时,在排气口以前就将气体排出,减少了因气体压力过大而消耗的功率,从而降低功率消耗。

英国GRIMM格林进口水环式真空泵技术参数:

zui大抽气量:0.15-120m3/min

水 耗 量:(4-5)~(220-260)L/min

进出口口径:25-300mm

限真空度:0.091-0.098MPa

转 速:590-2900r/min

功 率:0.81-185kw

英国GRIMM格林进口水环式真空泵适用范围:

广泛应用于机械、石油、化工、制药、食品、陶瓷、制糖、印染、冶金等行业。由于在工作过程中,该泵对气体的压缩过程是在等温状态下进行的,因此在压送和抽吸易燃、易爆气体时,不易发生危险,所以其应用更加广泛。

UK GRIMM imported water ring vacuum pump summary:

imported water ring vacuum pumps and compressors are used to pump or press gas and other gases without corrosion, insoluble and non solid particles, so as to form a vacuum or pressure in a closed container to meet the requirements of the process flow. A small amount of liquid is allowed to be mixed in the gas that is inhaled or pressed.

UK GRIMM imported water ring vacuum pump working principle:

The impeller is eccentrically installed in the pump body, so when the impeller rotates, the water is driven by the centrifugal force and forms a rotating water ring on the inner wall of the pump body. The inner surface of the upper part of the water ring rotates along the arrow direction tangent to the hub, and the inner surface of the water ring is gradually separated from the hub during the first half process, because this forms the closure between the impeller blades and the water ring. In space, with the rotation of the impeller, the space gradually expands, the pressure of the space gas is reduced and the gas is entered into the space. In the back half process, the inner surface of the water ring is gradually close to the hub, the space between the blades gradually diminishing, the pressure of the space gas rises, and the gas between the blades is discharged when it is higher than the vent. Every time the impeller rotates one week, the space between the blades is sucked up once, and many spaces work continuously, and the pump continuously suck or pressurized the gas.

In the process of work, doing work to produce heat, will make the working water ring heat, while a part of the water and gas are discharged together, therefore, in the working process, the pump must be continuously supplied to the pump to cool and supplement the water consumed in the pump to meet the work requirements of the pump.

When the gas of the pump is no longer used, there is a gas water separator at the end of the pump (which can be replaced by a water tank.) the waste water and the part of the water are discharged into the gas water separator. The gas and water are separated, the gas is discharged from the exhaust pipe, and the water left behind is supplied to the pump to continue to use. With the prolongation of working time, the temperature of the working water will increase continuously. At this time, a certain cold water (tap water) should be supplied from the water separator of the gas water separator in order to reduce the temperature of the working water, so as to ensure that the pump can meet the required technical requirements and indicators.

When used as compressor, the exhaust port of the pump is connected with a gas water separator, the gas water mixture enters the gas water separator and automatically separates. The gas is transported from the exhaust pipe to the required system and the working water is discharged automatically through the switch. When the gas is compressed, the working water is extremely hot, the water is discharged from the pump outlet and the temperature will become higher because of the water. At the bottom of the gas water separator, it is necessary to supply cold water continuously to supplement the hot water that has been released, and to cool the working water, so that the working water temperature is not too high, thus ensuring the performance of the compressor, reaching the technical index, and meeting the technical requirements.

UK GRIMM imported water ring vacuum pump structure description:

The imported water ring vacuum pump is composed of pump body, two end covers, impeller, shaft and other components. The intake and exhaust pipes are connected to the pump cavity by the suction hole and the exhaust hole installed on the disc of the end cover. The shaft is installed in the pump body eccentrically, and the impeller is fixed on the shaft with a flat key. The total gap between the two end surfaces of the water ring vacuum pump is adjusted by the cushion between the pump body and the disc. The clearance between the impeller and the end cap is adjusted by the SK-1.5/3/6 or the back cap (SK-12/20/30), and the above axis of the SK-42 is in interference with the impeller. The gap is determined by the front end positioning, and the SK-42/60/85/120 is no shaft. The rest of the structure is the same as that of SK-6/12/20/30. The clearance between the two end faces of the impeller and the end plate determines the size and ultimate pressure of the gas flow in the pump chamber from the intake port to the exhaust port.

The packing of the imported water ring vacuum pump is installed in the two ends of the cover, and the sealing is not entered through the small hole in the end cover, and the cooling filler is reinforced and the sealing effect is enhanced. The replenish water needed for the impeller to form a water ring is supplied by the water supply pipe, and the water supply pipe can be connected with the gas water separator to circulate water supply.

The SK type water ring vacuum pump adopts the mechanical seal in the form of sealing, and the mechanical seal is installed in the packing cavity, and the packing is omitted. The packing gland is replaced by a mechanical seal gland and the rest of the structure is the same.

The bearing is fixed on the shaft by the nut of the garden.

The imported water ring vacuum pump is equipped with a garden disk on the end cover, and there are suction, vent holes and rubber ball valves on the orchard. The effect of the rubber ball valve is that when the gas pressure between the blades of the impeller reaches the exhaust pressure, the gas is discharged before the vent, reducing the power consumed by the excessive pressure of the gas, thus reducing the power consumption.

UK GRIMM imported water ring vacuum pump technical parameter:

Maximum pumping capacity: 0.15-120m3/min

Water consumption: (4-5) ~ (220-260) L/min

import and export caliber: 25-300mm

Limit vacuum degree: 0.091-0.098MPa

Speed: 590-2900r/min

Power: 0.81-185kw

UK GRIMM imported water ring vacuum pump scope of application:

Widely used in machinery, petroleum, chemical, pharmaceutical, food, ceramics, sugar, printing and dyeing, metallurgy and other industries. In the process of working, the compression process of the pump is carried out in an isothermal state, so it is not easy to be dangerous when flammable and explosive gas is pressed and pumped, so its application is more extensive.

进口水环式真空泵:/product/2020-5-10/1355.html

GRIMM:

上海秉奇阀门有限公司为GRIMM公司在的总代理,是拥有GRIMM代理权及销售权,主要为地区客户提供服务与技术支持,同时,秉奇人员也积参与总部技术培训学习,并不断掌握产品原理、实际运作、工程技术做为基石,完善对地区客户需求。

关于GRIMM:

英国格林(GRIMM)有限公司是亚太地区流体控制领域的主要生产和供应商之一,公司总部位于克莱福德,拥有一支有经验的研发队伍,实行统一设计,统一标准,在水泵领域内处于ling先地位。在许多个均有生产水泵基地,由上海秉奇阀门负责市场各项业务与技术支持中心,同时向市场销售。

英国格林(GRIMM)产品已广泛应用于市政给排水、建筑、石油、化工、液化气、食品、制药、发电、冶金、矿产、锅炉蒸汽系统、压力容器、原子能、航空、火箭等各领域,以及人们日常生活中。

英国格林(GRIMM)主要产品有:管道泵、离心泵、隔膜泵、磁力泵、真空泵、潜水泵、排污泵、计量泵、卫生级泵、罗茨风机等系列产品。

服务体系:

GRIMM品质:

GRIMM公司注重产品质量及使用寿命,全部采用制造技术和生产设备,并坚持不懈研发新产品,为确保不间断的全过程质量控制,在生产过程中采用(SPC)过程控制和(TQM)质量管理;GRIMM的严格规范实现了不让品质拖节,有效保障产品每个细节达到的性能指标。

GRIMM专业:

掌握核心的流体控制技术,提供市场ling先的产品、服务和解决方案,帮助用户提率,带来至关重要的基础设施。

GRIMM服务:

我们与用户紧密合作,支持一系列系统使用技术和文件报告,提供售前、售中、售后服务和技术支持,有了您的信任与支持,我们将更完善、更提供水泵流体技术方案。

GRIMM china:

Shanghai Bingqi Valve Co., Ltd. for GRIMM company general agent in China, is China with GRIMM proxy and sales rights, provide service and technical support, mainly for Chinese customers at the same time, will also actively participate in the training of technical personnel of butterfly learning headquarters, and continue to grasp the product principle, practical operation and Engineering Technology based on customer demand, improve the Chinese area.

about GRIMM:

Uk GRIMM International Co., Lid is the field of fluid control in the Asia Pacific region is one of the main production and suppliers, the company headquarters is located in Clay Forde, has an experienced R & D team, the implementation of a global unified design, unified standards, a leading position in the field of water pump. In many countries, there are production pump base, China by the Shanghai Bingqi valve, responsible for the Chinese market business and technical support center, while selling to the Chinese market.

Uk GRIMM products have been widely used in various fields for municipal drainage, construction, petroleum, chemical, gas, food, pharmaceutical, power generation, metallurgy, mining, boiler steam system, pressure vessel, atomic energy, aerospace, rockets, and people's daily life.

Uk GRIMM the main products are: pipeline pump, centrifugal pump, diaphragm pump, magnetic pump, vacuum pump, submersible pumps, sewage pumps, metering pumps, sanitary pump, blower and other products.

Service system:

GRIMM quality:

GRIMM company pays attention to product quality and service life, all adopt the advanced manufacturing technology and production equipment, and unremittingly research and development of new products, the whole process of quality control to ensure uninterrupted, used in the production process (SPC) process control (TQM) and total quality management; strictly regulate the implementation of GRIMM has not let the quality drag day, effectively guarantee the performance of each product details.

GRIMM major:

Fluid control technology master core, market leading products, services and solutions that help users improve efficiency, bring critical infrastructure.

GRIMM service:

We work closely with the user, support a series of system using technology and file reports provide pre-sale, sale, customer service and technical support services, with your trust and support, we will be more perfect and more efficient to provide technical solutions of fluid pump.

英国格林总代理商:上海秉奇阀门有限公司,咨询:

Uk GRIMM total agents: Shanghai Bingqi Valve Co., Ltd., WeChat Advisory:

本页产品

进口真空泵前十名:进口真空泵品牌

进口真空泵品牌

进口真空泵品牌产品介绍:

两级水环式真空泵—大气喷射泵机组被用于抽取空气和其它无腐蚀性、不溶于水、不含有固体颗粒的气体以便在密闭容器中获得较高真空。

两级水环式真空泵 被广泛应用于食品、编织化工、医药和冶金工业及电子领域的真空蒸发、真空浓缩、真空回潮、真空浸渍、真空干燥及真空冶炼等。具有真空度高、在高真空区抽速大及结构紧凑、工作可靠、维修方便等特点。

2SK型适用于吸入压力低于-0.08MPa的工况条件。适用于吸入压力低于-0.096MPa的工况条件,在配用大气泵时,极限真空度可达-750mmHg。

进口真空泵品牌产品工作原理:

两级水环式真空泵工作原理如图一所示,叶轮(5)偏心地装在泵体(3)内,当叶轮旋转时,水受离心力的作用向四周甩出,在2SK型水环式真空泵体内壁与叶轮之间形成旋转水环(6)。水环上部内表面与叶轮轮毂相接触,当叶轮沿顺时针方向转动时,在前半转的过程中,水环内表面逐渐与轮毂脱离,相邻两叶片之间所形成的空腔逐渐增大,被抽气体通过泵进气管(4),经月牙形吸气孔(7)不断被吸入空腔内;后半转的过程中,水环内表面逐渐与轮毂接近,两相邻叶片之间空腔逐渐缩小,气体被压缩,因而压力不断增加,当压力增加到大于外界压力时,气体被排出,从而不断地抽走密封容器的气体,使其形成一定的真空。

进口真空泵品牌产品特点:

1、单级水环真空泵而言,具有真空度高、在高真空区抽速大等特点。

2、相同抽速率下,轴功率明显高于水环式真空泵。

3、因结构为双叶轮结构,制造、维修较为复杂,易损件较多。

进口真空泵品牌适用范围:

水环式真空泵和两级水环真空泵—大气喷射泵机组被用于抽取空气和其它无腐蚀性、不溶于水、不含有固体颗粒的气体以便在密闭容器中获得较高真空。它被广泛应用于食品、编织化工、医药和冶金工业及电子领域的真空蒸发、真空浓缩、真空回潮、真空浸渍、真空干燥及真空冶炼等。具有真空度高、在高真空区抽速大及结构紧凑、工作可靠、维修方便等特点。水环式真空泵适用于吸入压力低于-0.08MPa的工况条件。两级水环真空泵适用于吸入压力低于-0.096MPa的工况条件,在配用大气泵时,极限真空度可达-750mmHg。工作真空范围为-0.03---0.08MPa。 两级水环式真空泵,具有真空度高、在高真空区抽速大等特点; 结构紧凑、维修方便; 应用范围广泛,可抽除含水蒸汽、易燃、易爆、含少量灰尘的、含少量液体的各种气体; 主要用水作为工作介质,维护费用低; 可以在较为恶劣的环境下工作。

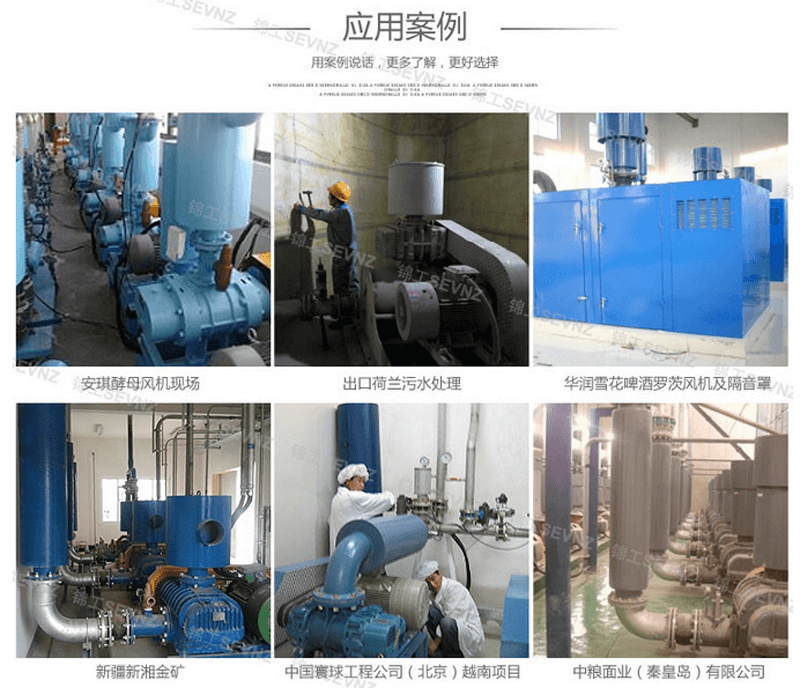

锦工以向客户提供全程顾问式服务为经营理念,向客户提供从研发设计、系统方案设计、制造过程、物流管理以及安装售后计划的制定与实施等解决方案。不断提升自身的研发及生产能力,为客户提供量身定制的产品和方案。想客户所需,因客户而变,我们始终坚持通过真诚的增值服务,达成我们和客户共赢的业务模式。

免费培训客户使用专用选型软件

成熟的系统设计工程,需要工程师更专业的投入。锦工深知这一点,因此愿意与我们的客户共享*的选型软件。软件人性化设计,让选型模式更智能更精准,告别旧时代的模糊查询,大幅提升工作效率,化繁为简,轻松高效。

构筑完善的服务网络体系

并且拥有一支系统组建的专业精良的售后服务团队,配备现场整机动平衡检测装置,可随时随地进行现场服务,帮助客户分析解决各种疑难问题。

(BACH)

Whole Course Consultant Service System

Bach's business philosophy is to provide full consultancy service to customers, providing them with solutions from R&D design, system design, manufacturing process, logistics management and installation after-sales plan formulation and implementation. Continuously improve their R&D and production capacity, to provide customized products and solutions for customers. We always insist on achieving win-win business model with our customers through sincere value-added services.

Free Training for Customers to Use Special Selection Software

Mature system design engineering requires more professional input from engineers. Bach knows this well and is willing to share the leading selection software with our customers. Software humanized design makes the selection mode more intelligent and accurate, farewell to the old era of fuzzy query, greatly improve work efficiency, simplify the complexity, easy and efficient.

Constructing a Perfect Service Network System

And has a professional and sophisticated after-sales service team set up by the system, equipped with on-site mobile balance detection device, can carry out on-site service anytime, anywhere, to help customers analyze and solve various difficult problems.

进口真空泵前十名:进口真空泵(工业传统品牌)锦工BACH品牌

进口真空泵(工业传统品牌)锦工BACH品牌

进口真空泵,进口品牌-进口水泵精选品牌-BACH锦工

结构及特点:

机泵同轴式直联设计,节省空间,易于安装;

采用机械密封作为标准配置,消除了泄露,维护简便;

运行平稳,噪音可低到62分贝;

统一的耐腐蚀设计青铜叶轮提高了泵的耐腐蚀性,不锈钢材质则更适用于更为苛刻的应用;

独特的柔性排报导口设计,不会产生过压缩

产品特性:

1、吸气口 连接木工雕刻机吸附管道,外径47mm

2、除尘罩 (用户选配):防止木屑等杂物进入泵内;

3、止回阀 停机时,防止泵内的水回流到真空台面内;

4、进水管 向泵内注入工作液(水),设备产生真空;

5、进水阀门控制工作液的流量,开机之前必须完全打开阀门,并确保水已经进入泵内,才能启动真空泵;

6、排水口 在设备使用10天左右,排空水箱内的工作液,更换干净的软化水;

7、排气口 在吸附过程中产生的气体,通过排气口排入大气,排气口不可堵塞,不可接超过两米的管路,不可接直径低于5cm的管路,否则极易超负荷,损坏电动机;

8、上水位口 向水箱内加水,直到上水位口向外淌水为止,并在每天启动真空泵前定时加水,保证水箱内有充足的工作液。

9、水箱 盛放工作液

适用范围:

1、可供冶金、化工、轻工、石油、医疗、制药、印染、电器、电真空、半导体、食品、原子能、纺织等科研机关、大专院校、工矿企业作科研和生产与教学之用。

2、由于旋片式真空泵是用黑色金属制造,而且比较精密,整个泵的工作都是与油联系在一起的,所以它不适用于抽除含氧过高的、有毒的、有爆炸性的浸蚀黑色金属的和对真空油起化学作用的各种气体,也不可做为压缩机和输送泵使使用。如有气镇装置的泵,可抽除一定量的可凝汽体。

3、旋片式真空泵可以用来直接获得真空度在10-3托以下的真空作业,以及配合其它真空设备获得真空度10-3托以上的真空作用之用。

泵是用来对抽除密封容器气体而获得真空的基本设备也是目前国内使用的真空泵,有水冷和风冷两种,本泵同国内同类产品相比具有真空度高,使用方便,安装,维护简单以及以下优点:

产品设计:

1.旋片式真空泵设有气镇阀,可抽除少量水蒸气;

2.旋片式真空泵的极限真空度高;

3.内装强制进油,润滑充分,性能可靠;

4.设有自动防返油双重保险装置;

5.保持进气压强为1.33×10Pa时仍可连续运转;

锦工简介

锦工,您可靠的合作伙伴

欢迎您来到锦工。我们集研发、生产、配套定制及专业服务为一体,为您提供完整、优质的配套,工艺及控制系统的解决方案。

锦工产品的价值主张是:可靠、便利、新颖。

2. 便利:便利是锦工产品的第二价值主张

客户的便利是锦工追求的重要目标。提供的便利,包括:

-- 产品覆盖范围宽广,产品线齐全完备,可供选择的产品类型丰富,为客户提供“一站式”解决方案,节约时间和精力。

-- 为客户提供特殊需求定制,专门产品定制,相关产品集成等系列服务,满足客户个性化需求或有效解决具体的施工难题。

-- 选型软件完善,提供技术细节完整详细,配件丰富,非常贴合施工和使用实际,节省大量的沟通澄清时间。

-- 提供敏捷的供货期,充分满足那些直到后一刻才得以决定下来的客户。

3.并非简单追求“与众不同”,而是追求“为客户创造价值的创新”

-- 结构更简单、合理;

-- 安装使用更方便;

-- 维修的负担少,综合拥有成本(TOC)低;

-- 更为敏捷务实的方法快速解决售后服务问题。

Brief Introduction to Bach

Bach, your reliable partner

Welcome to Bach. We integrate R&D, production, matching customization and professional services to provide you with complete and high quality matching, process and control system solutions.

The value proposition of Bach's products is reliable, convenient and novel.

Bach's long-term adherence to R&D capability innovation, manufacturing strength building, quality system building, and customer service improvement, focusing on improving the reliability of products and services, are all reliable and necessary conditions.

Reliability comes first of all from strong strength. In the stage of product research and development, it is checked repeatedly and verified carefully to improve reliability.

Secondly, we must rely on the powerful agile manufacturing capability, which is based on equipment hardware and integrated by lean management.

Third, the construction of quality assurance system and the implementation of products.

Finally, self-management alone is not enough. A large number of third-party certification of the arduous process, so that Bach products have experienced painful transformation repeatedly, and gradually become mature and reliable.

2. Convenience: Convenience is the second value proposition of Bach's products

Customer convenience is an important goal of Bach. The facilities provided include:

The products cover a wide range, complete product line and abundant product types are available, providing customers with "one-stop" solutions, saving time and energy.

- Providing customers with special needs customization, special product customization, related product integration and other series of services to meet customer personalized needs or effectively solve specific construction problems.

- Perfect selection software, complete and detailed technical details, rich accessories, very suitable for construction and practical use, saving a lot of communication and clarification time.

Provide an agile delivery date to fully satisfy customers who have not been able to decide until the last minute.

3. It is not a simple pursuit of "distinctiveness", but the pursuit of "innovation to create value for customers".

- Simpler and more reasonable structure;

- Easier installation and use;

- Low maintenance burden and low TOC;

- A more agile and pragmatic way to quickly solve the problem of after-sales service.

试论罗茨鼓风机选型设计 大风量罗茨鼓风机 罗茨鼓风机优点

山东锦工有限公司

地址:山东省章丘市经济开发区

电话:0531-83825699

传真:0531-83211205

24小时销售服务电话:15066131928